Need professional treatment for heavy-duty parts? We provide comprehensive solutions including electrophoretic coating, flat paint baking, and sandblasting.

Electrophoretic coating utilizes electrochemical principles to uniformly deposit paint onto metal surfaces. It penetrates complex structures and tiny crevices, forming a smooth, highly adhesive protective film. The coating offers excellent corrosion resistance, anti-rust properties, and durability, and can serve as a base layer for subsequent painting processes.

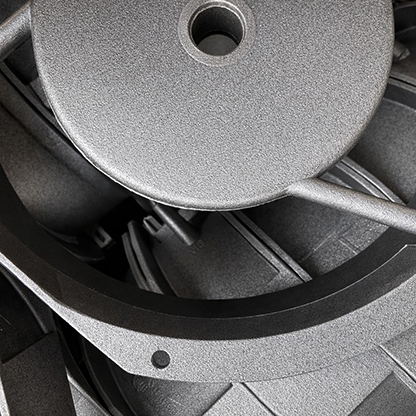

Sandblasting treatment utilizes high-speed sand flow to clean metal surfaces, removing rust, old paint, and oxide layers, while creating optimal adhesion conditions for subsequent coating. This process can improve surface roughness, uniformity, and texture, and also achieve surface cleaning and strengthening effects.

Liquid flat baking paint can present a smooth and even surface texture, with saturated colors that can be adjusted according to requirements. Through professional spraying and constant-temperature baking, the paint adheres firmly and offers excellent weather resistance and UV protection, meeting customized appearance demands.

Anti static coating can effectively reduce static electricity accumulation, prevent dust adsorption and electrostatic discharge damage. Commonly used in electronic device casings, medical equipment, and precision industries, it has good conductivity and durability, providing a stable and safe protective layer.